热塑性弹性体(TPE)具有硫化橡胶的物理机械性能和热塑性塑料的工艺加工性能。由于不需经过热硫化,使用通用的塑料加工设备即可完成产品生产。这一特点使橡胶工业生产流程缩短了1/4,节约能耗25%~40%,提高效率10倍~20倍,堪称橡胶工业又一次材料和工艺技术革命。

-

医疗及食品领域

-

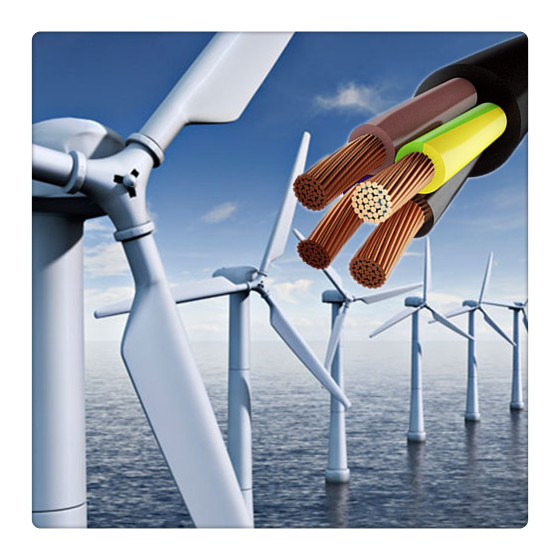

绿色能源TPE电缆

-

汽车用TPE电线电缆

-

海洋船舶弹性体电缆

-

TPE通用领域

TPE符合绿色环保之潮流及医疗食品卫生性,优良的耐药品性,良好的触感,增加了产品的功能及舒适性。应用案例;医疗管,一次性输液器,防毒面罩,瓶塞,洗耳球等。 符合食品接触卫生性,耐高温及耐低温,可满足食品器具全面之要求。TPE触感舒适,止滑,容易配成多彩的颜色,便于发挥设计灵感,令生活更多姿多彩。应用案例:餐具手柄,餐具勺、叉,盖子,防滑杯垫,冰箱冰格,等。

|

产品名称 |

牌号 |

产品特点及用途 |

|

高透明热塑性弹性体注塑料 |

MG80021-GT |

高透明、高环保、高耐磨,用于医用面罩、血袋、奶嘴、玩具、承重脚轮等 |

|

高透明热塑性弹性体挤出料 |

MG80022-GT |

高透明、高环保、高耐磨、高强度,用于输液器、止血带、特殊透明挤出产品等 |

如若以上没有您所需的材料,我们的客户定制业务将满足您对材料的各种需求!