美昱的医疗器械改性材料主要应用在各种医疗器械的注塑和挤出工艺上。我们专业技术人员会仔细地选择原材料,通过完善的配方和工艺设计,精心制造。产品能稳定地承受伽马等电子束照射灭菌,环氧乙烷灭菌和蒸汽加热消毒灭菌,并保证最少的颜色变化,同时达到相关的生物相容性和化合物的稳定性要求。按照客户的要求,我们的产品类别分含有邻苯二甲酸盐系列和不含邻苯二甲酸盐系列。产品的硬度范围从Shore 45A至Shore70D,所有等级都能够符合美国药典VI级。我们及时谨慎关注相关市场产品的医疗法规变化,审核我们的产品材料组份的安全合法性,确保将最安全的产品交给客户。

-

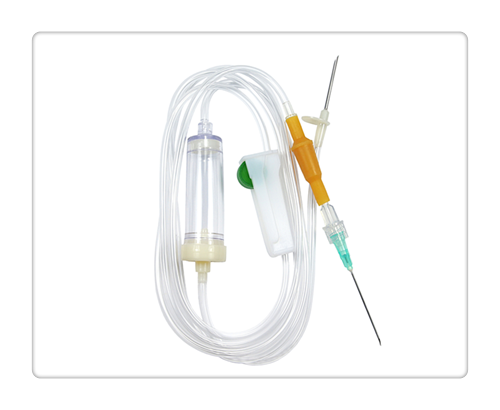

输液科

-

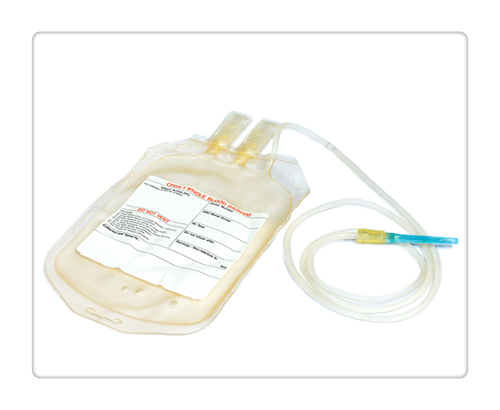

血液科

-

泌尿科

-

消化科

-

呼吸科

-

医疗及食品领域

-

手术用耗材

此系列产品应用于输液(血)用产品。高品质的外观,低味或几乎无味,可进行环氧乙烷或Gamma灭菌,安全无毒,符合GB15593-1995和ISO10993 Class VI,硬度和颜色可根据客户要求定制。

|

系列 |

等级 |

硬度范围 |

成型方式 |

特点 |

应用 |

|

普通输液管 |

软质 |

75-82A |

挤出 |

高透,无晶点,输液时管壁无挂现象,生物相容性好 |

普通输液器专用 |

|

输液滴斗 |

软质 |

75-90A |

注塑&挤吹 |

高透,高流动,易脱模,生物相容性好 |

普通输液器专用 |

|

避光输液管 |

软质 |

75-82A |

挤出 |

过滤290-450nm波长光,无脱色,生物相容性好 |

对光敏感的特殊药物专用 |

|

避光输液滴斗 |

软质 |

75-90A |

注塑&挤吹 |

过滤290-450nm波长光,高流动,易脱模,生物相容性好 |

对光敏感的特殊药物专用 |

|

硬针座 |

硬质 |

75D |

注塑 |

全硬质,高刚性,高流动,易脱模,灭菌后尺寸稳定,生物相容性好 |

输液针座 |

|

过滤器 |

半硬 |

65D |

注塑 |

易成型,不变形 |

装置过滤膜 |

|

硬三通 |

硬质 |

65D |

注塑 |

半硬质,高流动,易脱模,灭菌后尺寸稳定,生物相容性好 |

输液管三通 |

如若以上没有您所需的材料,我们的客户定制业务将满足您对材料的各种需求!